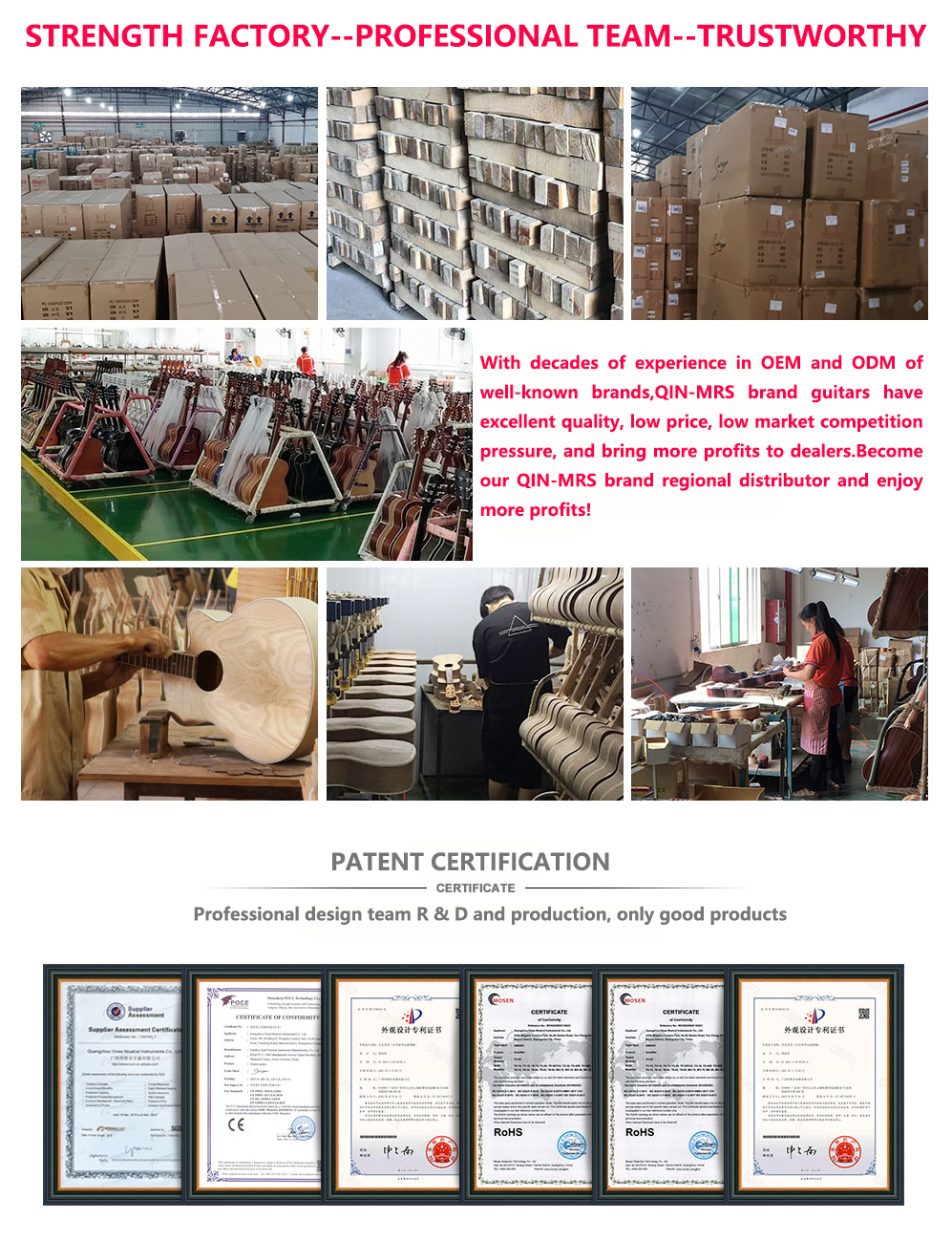

In an increasingly competitive musical instrument retail market, "product differentiation" has always been a core weapon for B-end clients (retailers, wholesalers, and brands) to stand out. A guitar factory capable of in-depth customization from product details to the overall design is precisely the key partner to help clients achieve this goal. As a professional guitar factory with 18 years of OEM/ODM experience, we have always centered our services on "clients’ brand needs," offering comprehensive customization services covering headstock logos, fingerboard inlays, and packaging design. Every guitar becomes a "mobile business card" for the client’s brand image, helping them establish unique brand recognition in the market.

1. Headstock Customization: Conveying Brand DNA at a Glance

As the "face" of a guitar, the headstock is the first visual focus for consumers and the core position for brand exposure. We understand the importance of headstock customization for clients’ brand communication, so we provide flexible and refined customization solutions to meet the style needs of different brands:

Logo Craft Customization

For clients focusing on quality, metal nameplate inlay or luminous logo craftsmanship can be selected to make the guitar more visually striking on stage or in displays. For clients with limited budgets, environmentally friendly screen printing (waterproof and wear-resistant, suitable for various headstock materials) is a cost-effective option. It supports multi-color overprinting, perfectly replicating the brand’s VI color system.

Headstock Shape Customization

In addition to classic headstock shapes such as Strat, Tele, and Les Paul, we also support clients in designing exclusive headstocks. Simply provide CAD drawings or hand-drawn sketches, and our factory’s R&D team will confirm details through 3D modeling, then use CNC precision cutting equipment for mass production. This ensures that the shape and edge curvature of each guitar’s headstock are completely consistent, eliminating the concern that "customized products = non-standard products."

Material & Surface Finish

Headstock materials can be customized in sync with neck materials (maple, roasted maple, flamed maple, etc.), and surface finishes support glossy, matte, or vintage distressed effects. For example, if a client focuses on a "vintage rock" brand style, a roasted maple headstock with a matte nitrocellulose finish can be paired with a distressed metal logo to instantly enhance the brand’s tone. For clients targeting younger consumer groups, a flamed maple headstock with a glossy finish can be used to highlight its delicacy.

2. Fingerboard Inlay Customization: Enhancing Brand Grade with Details

Fingerboard inlays are not only "decorative symbols" of a guitar but also the finishing touch that reflects a brand’s texture and craftsmanship standards. Based on the brand positioning of different clients, we provide fingerboard inlay customization services ranging from entry-level to high-end, ensuring every detail aligns with the brand’s tone:

Inlay Material & Pattern Customization

Entry-level brands can choose ABS material inlays (cost-effective with rich colors). Mid-to-high-end models can opt for shell (abalone shell, mother-of-pearl) or metal material inlays, and support customization of exclusive brand patterns. For instance, a cooperating UK guitar brand designed its brand initial "W" into a simple geometric inlay pattern, paired with a rosewood fingerboard—understated yet highly recognizable. Another client chose "constellation" and "musical note" themed inlays to align with its positioning as a "youthful music trend brand."

Inlay Position & Specification Customization

In addition to regular fret marker inlays (at frets 3, 5, 7, 9, 12, 15, 17, 19, 21/22), we also support inlaying "exclusive brand markers" at the 12th fret (e.g., brand logo abbreviations, mascot patterns) or "limited-edition serial numbers" at the end of the fingerboard (suitable for high-end customized models to enhance collection value). Inlay specifications can be adjusted according to the fingerboard size to ensure proportional coordination without affecting playing feel.

Material Compatibility Assurance

For example, rosewood fingerboards are relatively soft, so we adopt the process of "shallow inlay + high-strength environmentally friendly adhesive" to avoid cracking. Roasted maple fingerboards have high hardness, so CNC precision grooving technology is used to ensure that inlay pieces are flush with the fingerboard surface without gaps—eliminating any sense of frustration during playing.

3. Packaging Design: Extending the Brand from Warehousing to Retail

Guitar packaging is not only a "protective tool" but also an extension of the brand image in warehousing, transportation, and retail links. We provide full-process packaging customization services from inner boxes to outer cartons, helping clients achieve brand consistency "from the factory to consumers’ hands":

Inner Box Customization

Inner boxes can be customized with color printing (printing brand logos, product selling points, and usage instructions), and materials can be selected from cardboard, EVA shockproof cotton, or wooden gift boxes. For music store clients, we design inner boxes with "brand stories" printed on the sides and transparent window designs on the front, facilitating the display of guitar appearance at exhibitions. For clients with high-end customized models, we provide wooden gift boxes with flannel linings and exclusive brand ribbons to enhance product grade.

Outer Carton Customization: Balancing Protection and Brand Exposure

Outer cartons use five-layer corrugated paper (with a compressive strength of 150kg, suitable for cross-border transportation). The surface can be printed with the client’s brand logo, contact information, and warning labels such as "fragile" and "moisture-proof." For e-commerce clients with bulk purchases, we also support printing "batch numbers" and "production dates" on outer cartons to facilitate inventory management. If there are overseas warehousing needs, we can customize outer cartons according to the size standards of overseas warehouses, effectively reducing warehouse space waste.

Accessory Customization: Strengthening Brand Memory

In addition to the packaging itself, we also provide synchronized customization services for exclusive brand accessories—such as guitar straps, picks, and cleaning cloths printed with brand logos, and even brand QR codes printed on guitar sound hole labels (scanning the QR code redirects to the brand’s official website or product tutorial videos). These small accessories not only increase the added value of the client’s purchased products but also allow consumers to continuously perceive the brand during use, thereby promoting repurchases and recommendations.

4. Customization Process: Simple, Efficient, and Quality-Controlled

Many clients worry that "the customization process is complicated and time-consuming." However, we have solved this pain point through a standardized customization service process:

Requirement Communication (1-2 Days)

Clients only need to provide brand VI manuals and customization requirements (e.g., vector graphics of headstock logos, fingerboard inlay sketches, packaging size requirements), and a dedicated product manager will issue a "customization plan" within 24 hours, clarifying materials, craftsmanship, costs, and timelines.

Sample Confirmation (15-20 Days)

After the plan is confirmed, we will prioritize sample production—samples of headstocks and fingerboard inlays can be made separately (to facilitate clients’ confirmation of details), and complete guitar samples will be delivered within 20 days. Clients can test the craftsmanship and feel before confirming mass production.

Mass Production Execution (30-45 Days)

After sample confirmation, the factory will conduct mass production in accordance with "customization standards." The QC team will check customization details (e.g., logo position, inlay flatness, packaging printing clarity) at each link to ensure that bulk products are consistent with samples.

Logistics & Delivery

We assist clients in specifying logistics methods (sea freight, air freight, courier) and attach "custom batch labels" to outer cartons to facilitate clients’ customs clearance and warehouse management.

We are always committed to "enhancing clients’ brand competitiveness" and providing guitar customization services that are "on-demand, quality-stable, and efficiently delivered." If you have guitar customization needs, please feel free to contact us—we will integrate your brand concept into every instrument!